Say NO to Waste

Eliminate waste in all areas of the supply chain

LEATHER HAS TREMENDOUS VALUE WHEN UTILIZED CORRECTLY

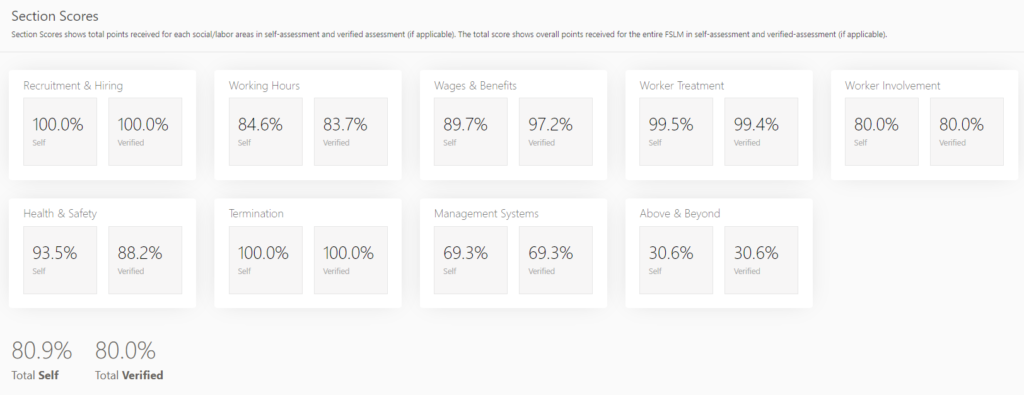

Asiatan is a tannery committed to changing the narrative behind leather.

Leather is the ultimate up-cycle material, so long as we do the right thing. Leather products last longer, have higher value and just work better than any other oil-based, synthetic material.